Main Idea:

Maintenance robots for industrial pipelines represent a significant technological advancement, bringing a major transformation to infrastructure management in industrial settings. These robots, equipped with intelligent mobility systems, advanced sensors, and pneumatic actuators, are capable of inspecting, detecting damage, and performing repair operations without the need to halt industrial activities. Their advanced design allows them to navigate long pipelines, complex paths, and confined spaces, leading to reduced operational costs and increased repair precision.

One of the most important innovations in this field is the use of soft robots with flexible actuators, which provide greater adaptability to the variable conditions inside pipelines. These robots, powered by pneumatic actuators and made from flexible materials, can easily maneuver through complex routes and perform internal repairs and coating tasks without exerting excessive pressure or causing damage to the pipeline structure.

Additionally, the integration of advanced imaging and remote sensing technologies enables these robots to detect and repair minor defects such as cracks, leaks, and internal corrosion at early stages, preventing more serious issues. The use of such robots significantly enhances worker safety, reduces repair time, and minimizes costs associated with industrial downtime—making them a highly valuable asset in modern industrial maintenance.

Explanation:

Maintenance of industrial pipelines has always been one of the major challenges across various industries. Piping systems used in oil and gas, petrochemical plants, urban infrastructure, and sewage networks are constantly exposed to damage such as corrosion, scaling, leakage, and cracking. Traditional repair methods for these pipelines are often costly, time-consuming, and high-risk. In many cases, they require excavation, disassembly, or even full replacement of pipe segments, which not only increases expenses but also disrupts the operational flow of fluid transport systems.

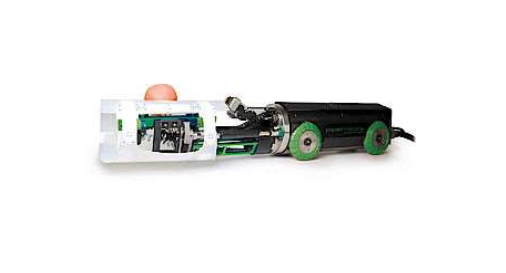

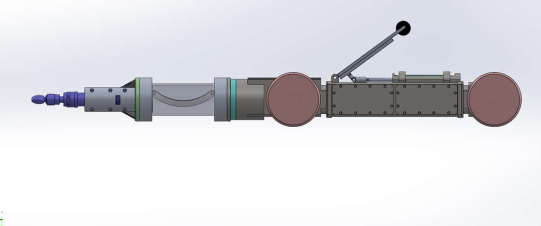

In this project, a fully pneumatic cutter robot has been developed—from initial design to manufacturing readiness—as an innovative, intelligent, and safe alternative to traditional methods, aiming to optimize pipeline maintenance and repair processes. This robot, equipped with intelligent mobility systems, advanced sensors, and pneumatic actuators, is capable of performing inspection, cutting, and repair operations using a sleeve-based injection system without requiring long industrial shutdowns. The robot is designed to operate within pipes ranging from 150 to 600 mm in diameter and can execute tasks with high precision.

A key feature of this robot is its complete resistance to water ingress and environmental contamination, making it suitable for challenging environments such as sewer networks, underground pipelines, and chemical liquid transport systems. Additionally, the robot includes an add-on repair module that can inject protective materials and apply internal coatings to restore damaged pipe sections and prevent the spread of cracks and leaks.

One of the most significant innovations in this project is the robot’s soft, pneumatic arm mechanism, which offers substantial advantages over traditional mechanical or hydraulic systems. This mechanism allows the robot’s tools to be finely adjusted, ensuring that no excessive force is applied to the pipe structure during cutting, drilling, or repair material injection. Moreover, the arm’s soft and flexible movement enhances adaptability to complex and irregular pipeline routes, improving the robot’s performance in difficult environments.

Unlike hydraulic systems that require constant, costly maintenance and may cause environmental issues due to oil leaks, the use of pneumatic actuators in this robot reduces overall system weight, increases response speed, and minimizes operational costs. This project offers a comprehensive and novel solution for industrial pipeline maintenance and repair. By leveraging advanced robotics technology, artificial intelligence, pneumatic actuators, and a soft-arm system, the robot delivers accurate, efficient, and safe performance. The designed robot can carry out maintenance tasks with minimal cost and maximum precision, extending the service life of pipelines and reducing the need for premature replacements. This technology marks a fundamental advancement in the management of industrial infrastructure and plays a crucial role in optimizing the maintenance of fluid transport pipelines.